Evaluation of the Treatment of Exhaust Air in the Aeration Tank

The exhaust air from aerated sand traps usually contains hydrogen sulfide, which is corrosive and in certain concentrations is harmful to health. At the WWTP Berlin-Schönerlinde exhaust air in the aerobic zone of the aeration tank will be treated for the first time by oxidizing hydrogen sulfide to non-hazardous sulfate. The successful technical implementation of this process step will be demonstrated under real conditions and examined in terms of its impact on engineering materials and economic efficiency. In addition, long-term investigations at the WWTPs Schönerlinde, Münchehofe and Waßmannsdorf are expected to deliver an optimized aeration regime with regard to its energy efficiency. In this context, the use of a “sliding pressure control” will be tested in comparison to a “constant pressure control”.

In the project ABLUFT 1, preliminary tests carried out at the WWTP Schönerlinde showed that it is possible to treat exhaust air from an aerated sand trap in the aerobic activated phase allowing for the oxidation of the corrosive and toxic H2S to non-toxic sulfate. In the ABLUFT 2 project, these processes will be monitored for the first time full-scale and under real conditions. Their impact on engineering materials and on their economic efficiency will be examined, too. In addition, it will be investigated whether this aeration regime can be operated also with larger flow rates of H2S containing exhaust air without causing any malfunctions in the biological wastewater treatment. Therefore, two aeration tanks will be equipped with additional aerators. Furthermore, the flow rate of the substitution of the main aeration with H2S containing exhaust air will be determined as well as possible changes in the composition of the biocenosis of the activated sludge and in the effluent quality. Furthermore, aerator elements of two different materials will be tested with H2S-containing air.

In addition to the treatment of exhaust air in the activated phase, an energy-optimized aeration regime will be derived from long-term investigations performed at the WWTPs Schönerlinde, Münchehofe and Waßmannsdorf. For this purpose, the use of a “sliding pressure control” will be tested in comparison to a “constant pressure control”.

Gas hoods on the activated sludge basin of half-line 3.2 in Schönerlinde

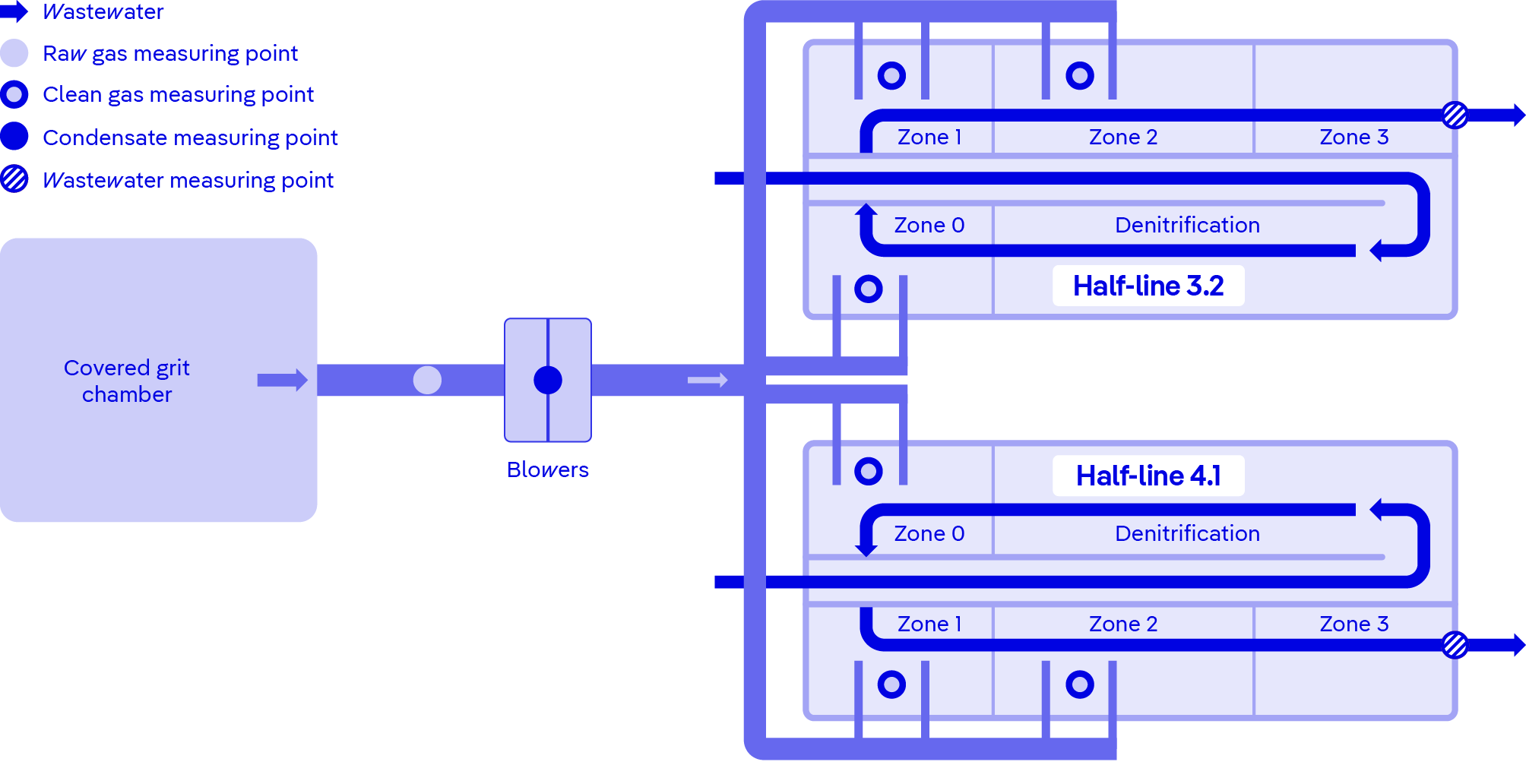

Process diagram of the system for waste air co-treatment in the aeration tanks